The production process is described in the production regulations and consists of the following phases.

The pig which the fresh hind leg for the preparation of Prosciutto di Modena is taken from must be a white breed and can originate in just ten regions of Central and Northern Italy. It must be at least nine months old, healthy, rested and weigh an average of about 160 kg, having been nourished during the last three months before slaughter with feed that limits fat intake to less than 10%. After slaughter, which must take place on an empty stomach, the thigh is jointed and then sent to the production plant, where it immediately undergoes the necessary checks.

The fresh hams considered suitable are placed in a special cell, where they spend the time necessary to allow the meat to reach the right, evenly distributed, temperature, which ensures the right consistency, facilitating the subsequent salting operation.

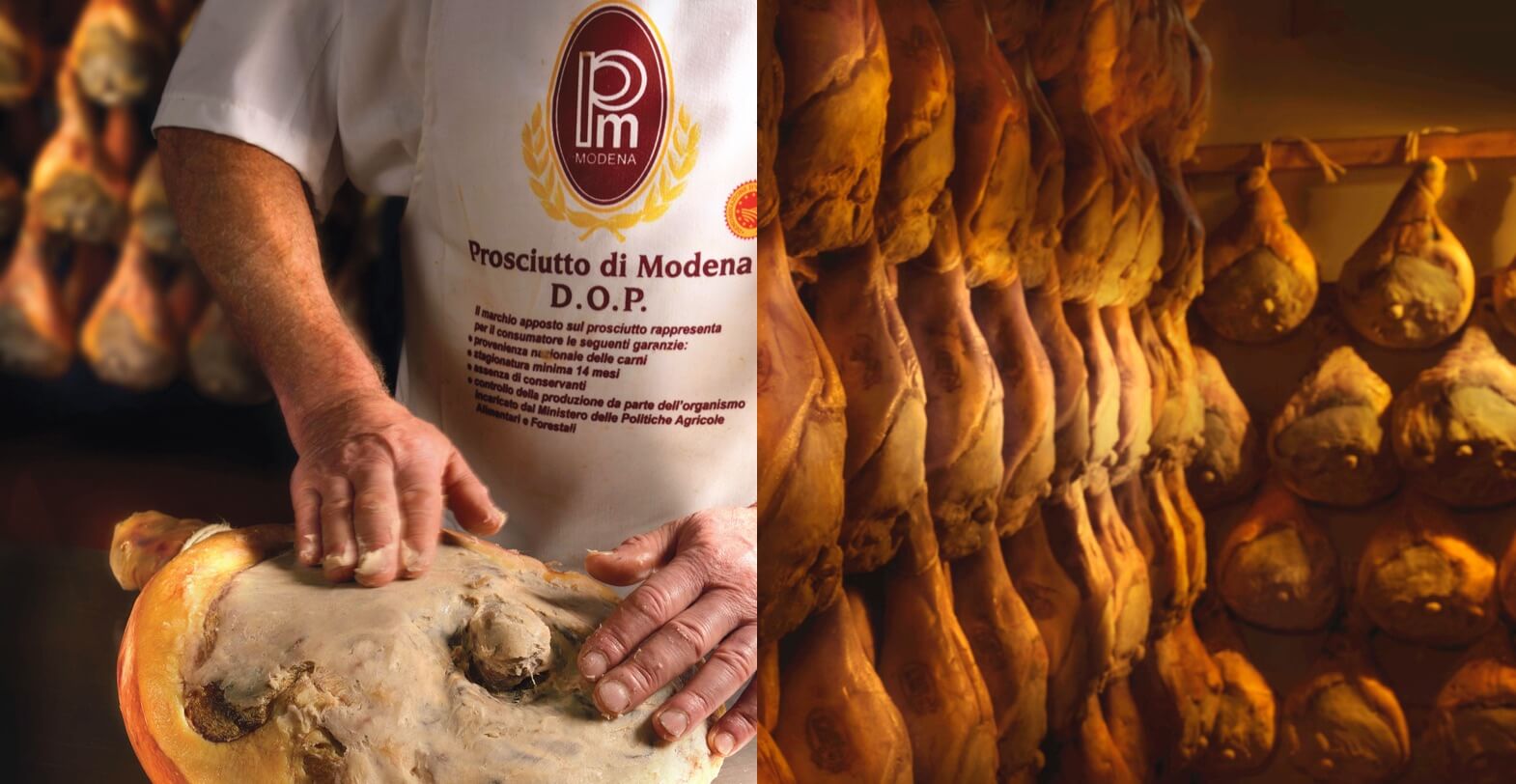

The trimming phase consists of removing fat and rind in order to give the ham its classic rounded "pear" shape. Hams used to produce Prosciutto di Modena must not be subject to any treatment other than chilling.

The trimmed hams are then salted in compliance with the following procedure: the hams are sprinkled with salt, covering both the exposed inner side and the rind. During this operation, the hams are laid on a horizontal surface. They are massaged, either before or during salting, by hand or mechanically, to prepare the meat to receive the salt and to check, by pressing it in specific points, that it is bleeding out perfectly.

Sodium chloride, usually pure sea salt, is used for salting, without any smoking process. The salted hams are stored on a horizontal surface at all times and are placed in a special cell, called the "first salt" cell, where they spend between five and seven days at a humidity-controlled temperature of between 0 and 4 degrees centigrade. They are then removed from the cell and the residual salt is removed from the surface. The massage is repeated and the ham is sprinkled with salt again, following the process described. The salted hams then spend another 12-15 days in the "second salt" cell, in the same environmental conditions, until the salting process has been completed. During the entire process, the prosciutto slowly absorbs salt and releases some of its moisture.

After removing the residual salt, the salted hams are placed in a special room, where they spend at least 60 days, depending on size and technological requirements, at a humidity-controlled temperature of between 2 and 5 degrees centigrade. During the resting phase, the salt absorbed gradually penetrates the muscle mass and is evenly distributed.

After resting, the ham is washed with water at a maximum temperature of 50/60 degrees centigrade. As well as performing a completely revitalising effect, washing removes all the surface formations produced during the salting and resting phases due to dehydration, and tones the outer tissues. Before washing, the hams are "groomed", refining the surface effects of the loss in weight.

After draining off the water, the hams enter the dryer at a temperature of 24/26 degrees centigrade, remaining there for between 5 and 10 hours depending on the quantity of the product, with a very high relative humidity. Once these levels have been reached, cold accumulators are used to initiate the real dehumidifying phase, which can last about a week depending on the loads and the way the equipment is used. The values vary in relation to the techniques involved in the next treatment, ageing.

The ageing phase can be divided into two sub-phases: pre-ageing and proper ageing. The ageing process usually lasts eight months; however, its duration is always related to the size of the batch and varies accordingly, taking into account the lower limits of the complete processing cycle described below.

During the ageing process, biochemical and enzymatic processes take place in the meat, completing the preservation process by determining the characteristic sensory priorities thanks to the contribution of the natural external environment (low humidity and natural ventilation, which determine the aroma and flavour of the product). The minimum duration of the overall process, from salting to the completion of ageing, comes to an end during the fourteenth month after salting; this duration may be shortened to end in the twelfth month, as long as the entire batch consists of hams with an initial weight of 13 kilograms or less.

No specific manufacturing processes take place during the ageing process, except for "sugnatura" (a greasing procedure all known as "filling"), which is carried out once or twice. The bare part of the prosciutto is smeared with a mixture of "sugna" or lard, salt, pepper and ground rice, applied thinly and evenly by hand. This preparation and its application are intended solely for technical functions of softening the bare outer surface of the prosciutto not covered with rind and protecting it from external agents, without jeopardising the continuation of the osmotic action.

Upon completion of the ageing process, the ham is subject to probing or drawing/pointing, which consists in probing the prosciutto in certain critical points with a bone needle or horse tendon, which absorbs the typical aromas of the prosciutto and releases them quickly. This operation is carried out by experts who are trained to recognise the successful progress of the ageing process based on the aromas.

After 14 months, the inspectors from the oversight body, having carried out the checks required by the production regulations, apply the brand that identifies Prosciutto di Modena PDO.